About Us

Integrity, quality, win-win

Modern Soot Blowing/Now Dai Zhizao

Over 29 years of development

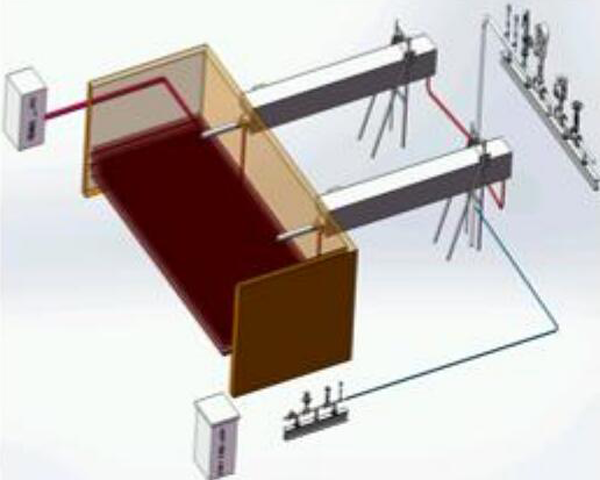

With independent research and development and production of a full range of boiler soot blower

harbin now dai intelligent equipment manufacturing co., ltd. was formerly harbin modern sootblowing technology co., ltd., is a commitment to all kinds of boiler sootblowing equipment research and development, production and sales of high and new technology enterprises. The company covers an area of 30000 square meters and an industrial plant of 8,000 square meters. The annual production of various types of boiler soot blowers can be matched with 500 boilers.

View Details →Products

The main products are fire high temperature exhaust fan, mixed oblique flow fan, cabinet type high temperature exhaust machine, air conditioning fan, induced fan, fire damper. Smoke exhaust valve, muffler, louver air vent, galvanized ventilation duct, fireproof air duct and various accessories required for ventilation works.

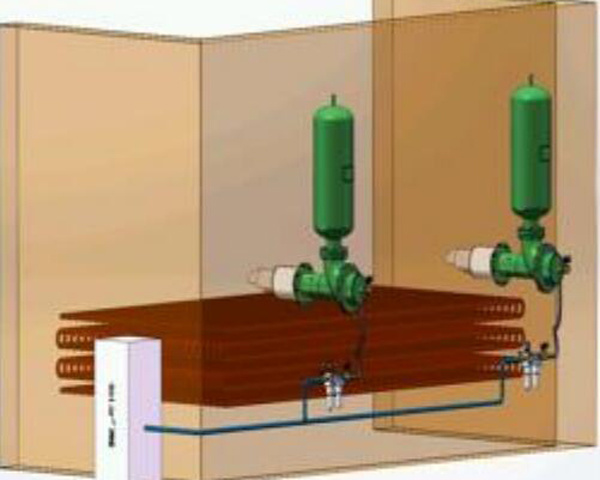

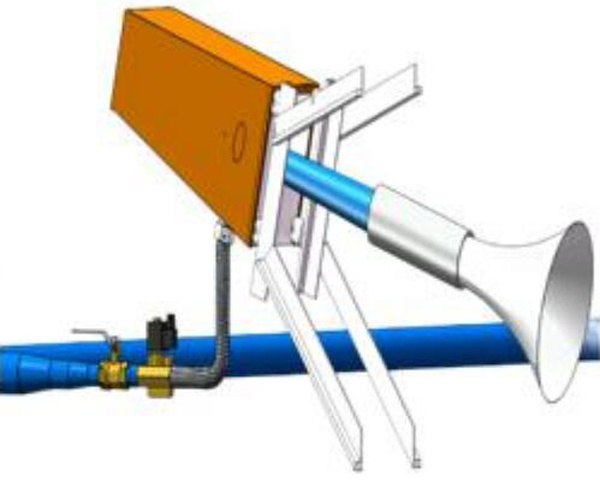

XD-2020ZC series steam soot blower

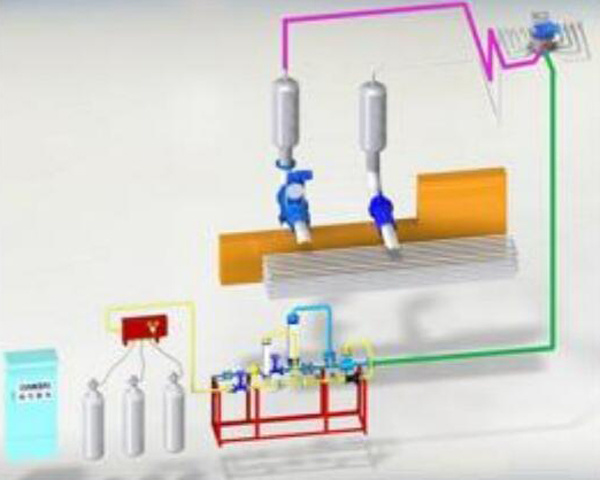

XD-2020 series gas soot blower

XD-QN series air energy dust blower

Application areas

Successfully used in electric power, petrochemical, oil refining, cement, metallurgy, pharmaceutical, paper and other industries.

Oil

Chemical

Steel

Thermal power

Waste incineration power generation

biomass power generation

Heating

News Center

Pay attention to the latest developments of the company, focus on the hot information of the industry

Our company has signed a supply contract with Datang Wuan Power Generation Co., Ltd.

Our company signed a supply contract with Datang Wu'an Power Generation Co., Ltd. in March 2011 for the Datang Wu'an Power Generation Project (2×300MW) for the new subcritical air-cooled circulating fluidized bed boiler pulse blowers project.

Our company has signed a supply contract with Hebei Yingxin Group Float Glass Co., Ltd.

Our company signed a supply contract for 2 pulse gas soot blowers for the waste heat boiler project with Hebei Yingxin Group Float Glass Co., Ltd. on March 24, 2011. This is our company's fourth cooperation with Hebei Yingxin Group and the third supply contract for pulse gas soot blowers with Float Glass Co., Ltd. On March 24, 2010, our company signed a supply contract for a pulse gas soot blower for a glass kiln waste heat boiler with this company, which was installed and debugged in June 2010, and passed the operational acceptance with excellent soot blowing results. Therefore, both parties signed a supply contract for soot blowers for 2 boilers on June 5, 2010, and the soot blowers have also been put into operation with good soot blowing results. The successful application of the pulse gas soot blowers produced by our company on multiple glass kiln waste heat boilers is the result of our technical and installation personnel prioritizing quality and service and working together. The company's technical personnel have communicated multiple times with manufacturers and design institutes during the design of each boiler, targeting the ash accumulation characteristics of the boiler for specific designs, striving to ensure that every designed soot blowing point achieves the desired soot blowing effect, while installation personnel provide prompt technical services. Our company regards quality and service as the first priority.

Shijiazhuang Yujing Glass Co., Ltd. Pulse Gas Blower Operation Acceptance Qualified

Our company signed a supply contract for pulse gas blowers with Shijiazhuang Yujing Glass Co., Ltd. for 2 glass kiln waste heat boilers on May 23, 2010, and the acceptance was completed on January 28, 2011, with the equipment put into use. We ensured that all documentation was complete, the equipment operated normally, and the blowing effect was good. The company dispatched excellent technical service personnel to be responsible for the installation and debugging of the equipment on-site, and participated in the performance acceptance test, assessing the equipment, which was found to fully meet the requirements upon acceptance. Our on-site service personnel were serious and responsible, actively cooperating with the user's construction, completing the installation work ahead of schedule, and the user was very satisfied with our product quality and technical services.

Our company signed a supply and installation contract for the pulse gas soot blower with Jiangsu Guoxin Rudong Biomass Power Co., Ltd. on June 24, 2011. This was for the installation of a pulse gas soot blower on a UG-110/9.8-J biomass boiler for Jiangsu Guoxin Rudong Biomass Power Co., Ltd. After the soot blower was put into operation for a period of time, due to its good performance, the customer expressed satisfaction, and both parties completed the project acceptance on October 19, 2011. The customer highly praised our company's Patented Products "pulse nozzle with spiral protective air device" and signed another supply and installation contract for the pulse soot blower on September 28, 2011, which has been running effectively ever since. This is our company's second success after achieving success in the ash cleaning of biomass boilers for China Energy Conservation (Suqian) Biomass Power Co., Ltd., marking that our company's ash cleaning technology for biomass boilers has completely matured and is approaching perfection.

Customer Service

Meet customer needs and exceed customer expectations

Professional customization, design the whole solution of ash accumulation. Economic benefit analysis, technical performance analysis report.

Sincerely look forward to working with you to create a better tomorrow

If you are interested in our products and need customized products, please leave us a message by inquiry.