Streamlined

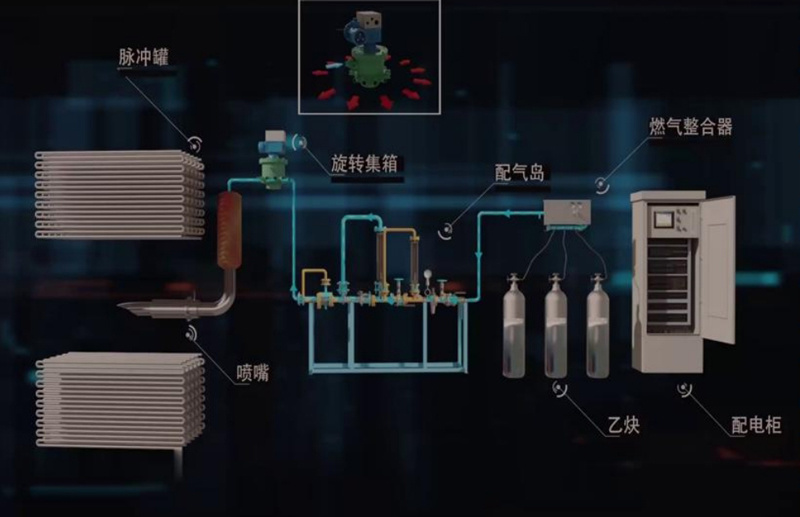

XD-2020 series gas soot blower

Using gas and air mixed in a certain proportion, a deflagration is generated in a specially designed turbulent tank. The combustion gases are suddenly released through a directional nozzle outlet, and through purging, acoustic fatigue, thermal cleaning, and vibration, the accumulated ash on the boiler's heating surface is removed. Finally, the fly ash is carried away by the flue gas flow, thereby improving the thermal efficiency of the boiler.

Key words:

Classification:

E-mail:

Product Description

01

Gas Source

02

Gas Integrator

03

Gas Regulation Control Island

04

Rotary Collector

05

Pulse Tank

06

Pulse Nozzle

Rotary Collector

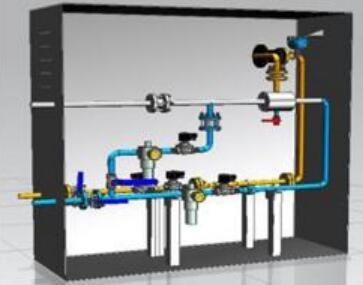

Currently, the distribution control device in the gas ash cleaning field of the international market is relatively advanced, with dual functions of distribution and ignition.

Simplified structure, ignition and distribution combined into one;

Central air intake, ignition inside the box, no combustible gas leakage, saving fuel;

The ash cleaning points do not interfere with each other, away from the gas regulation control island, making the entire system safer;

The application of the rotary collector eliminates the situation of multiple electric valves on several branches;

Minimal maintenance and repair, can operate safely for a long period;

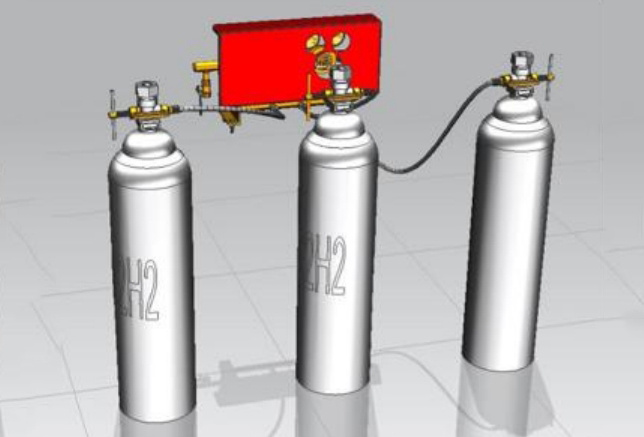

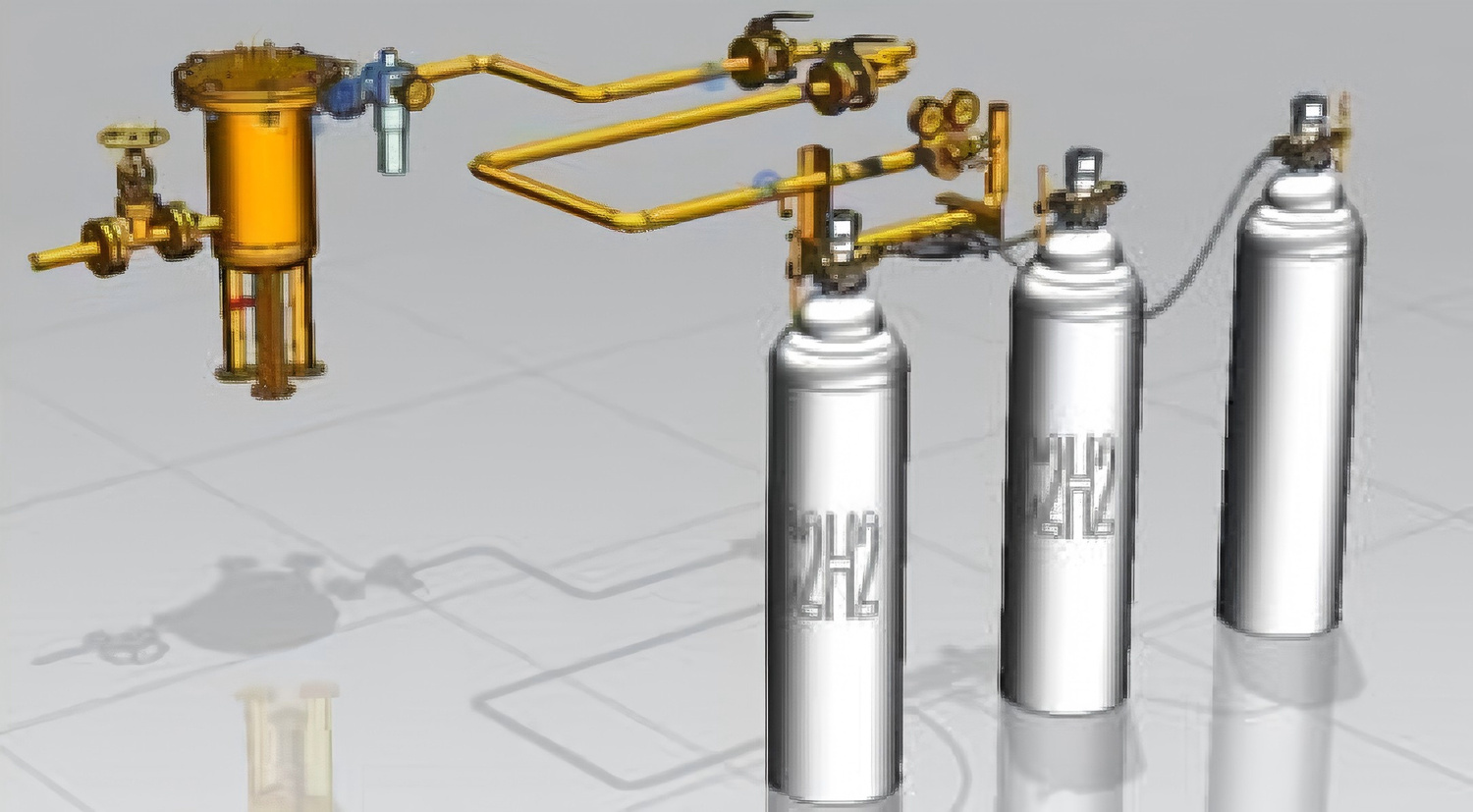

Gas Integrator

Aesthetic appearance, more compact structure, small footprint, easy installation;

Stainless steel flexible hose replaces high-pressure rubber hose, with a longer service life, effectively avoiding the disadvantages of high-pressure rubber hoses such as aging and gas leakage;

A limit ring has been added to restrict the maximum pressure adjustment, effectively protecting the equipment, ensuring full utilization of gas, and saving gas;

The gas integrator adopts an 'open' gas supply system, ensuring that the storage of acetylene gas for the ash cleaner meets the regulations of the national fire department.

Using three 40L standard dissolved acetylene cylinders for manifold and pressure reduction, reliably ensuring that the gas in all acetylene cylinders can simultaneously meet the national standard requirement for minimum residual pressure, eliminating waste, and the gas integrator is equipped with a dry flame arrestor to effectively prevent backfire in the system.

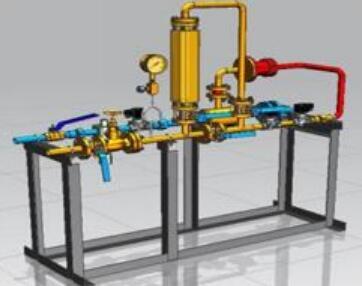

Gas Regulation Control Island

Model: PB5, PB6, PT5-G, PT5-Z, PTB5-Z

A device that integrates the regulation and control of air and gas flow, pressure, automatic gas distribution and purging control, uniform mixing control of air and gas, gas pipeline flame arresting, and prevention of gas flow backflow.

Air pressure reduction, filtration;

Dual explosion-proof solenoid valve automatic control;

Air and gas flow regulation, metering unit;

Uniform mixing of air and gas;

Flame arresting and backflow prevention device;

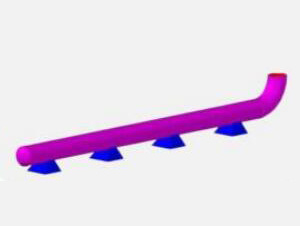

Pulse Tank

Pulse Tank

A tank for explosive combustion of mixed gases, producing high temperature, high pressure, and high decibel pulse waves during the explosive combustion process.

Eight different energy level pulse tanks, selecting reasonable and effective pulse tank models according to different types of boilers and different locations.

01

The air intake structure and the internal structure of the tank optimize the use of flame arresting technology, effectively preventing backfire in the system.

02

Top air intake structure, ensuring that the gas distribution fullness reaches 95%.

03

Using a single branch, accurately calculating gas distribution time to adapt to the energy adjustment required for different ash accumulation.

Serial Number | Name | Model | Material | Size | Volume (m3) | Tank Size | Pulse Tank Inlet Size | Pulse Tank Outlet Size | Weight |

1 | Pulse Tank | MA2-Ⅲ | Assembly | φ325×1220 | 0.0723 | φ325 | φ38 | φ159 | 58 |

2 | Pulse Tank | MB2-IⅡ | Assembly | φ273×1161 | 0.0434 | φ273 | φ38 | φ133 | 45 |

3 | Pulse Tank | MC2-Ⅱ | Assembly | φ219×1100 | 0.0228 | φ219 | φ38 | φ108 | 33 |

4 | Pulse Tank | ME2-Ⅱ | Assembly | φ377×1274 | 0.0904 | φ377 | φ38 | φ159 | 97 |

5 | Pulse Tank | MF2-Ⅱ | Assembly | φ426×1382 | 0.1221 | φ426 | φ38 | φ219 | 114 |

6 | Pulse Tank | MG2-Ⅱ | Assembly | φ377×1303 | 0.0904 | φ377 | φ38 | φ180 | 98 |

7 | Pulse Tank | MH2-IV | Assembly | φ426×2155 | 0.2218 | φ426 | φ38 | φ219 | 189 |

8 | Pulse Tank | MN2-Ⅱ | Assembly | ①426×1355 | 0.1221 | φ426 | φ38 | φ194 | 112 |

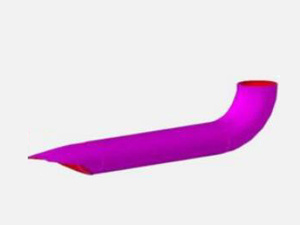

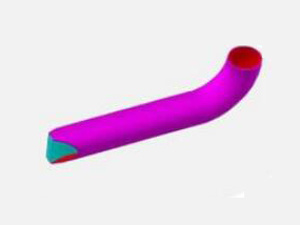

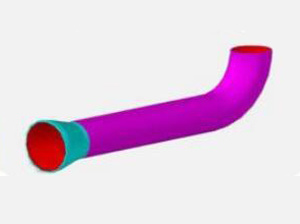

Pulse Nozzle

The pulse wave after detonation propagates in the form of a spherical wave along the normal direction of the nozzle outlet.

Four types of 24 nozzles have been developed, designed specifically according to the different boiler types, fuels, heating surface structures, smoke temperatures, etc.

For special working conditions such as high temperature and high corrosion, various wear-resistant and corrosion-resistant nozzle materials containing Ni-based, Zn-based, and Cu-based rare earth elements have been developed.

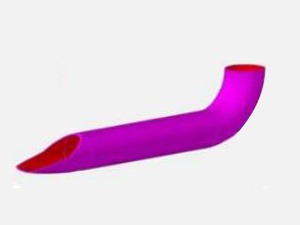

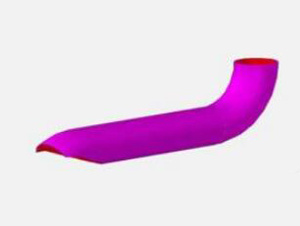

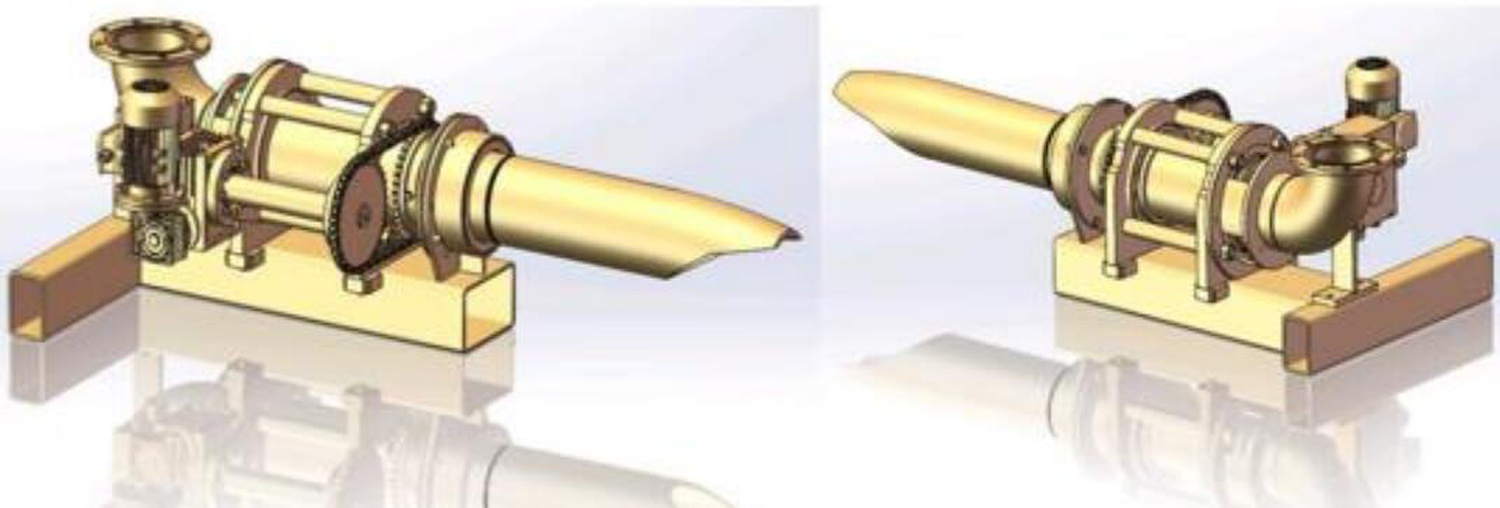

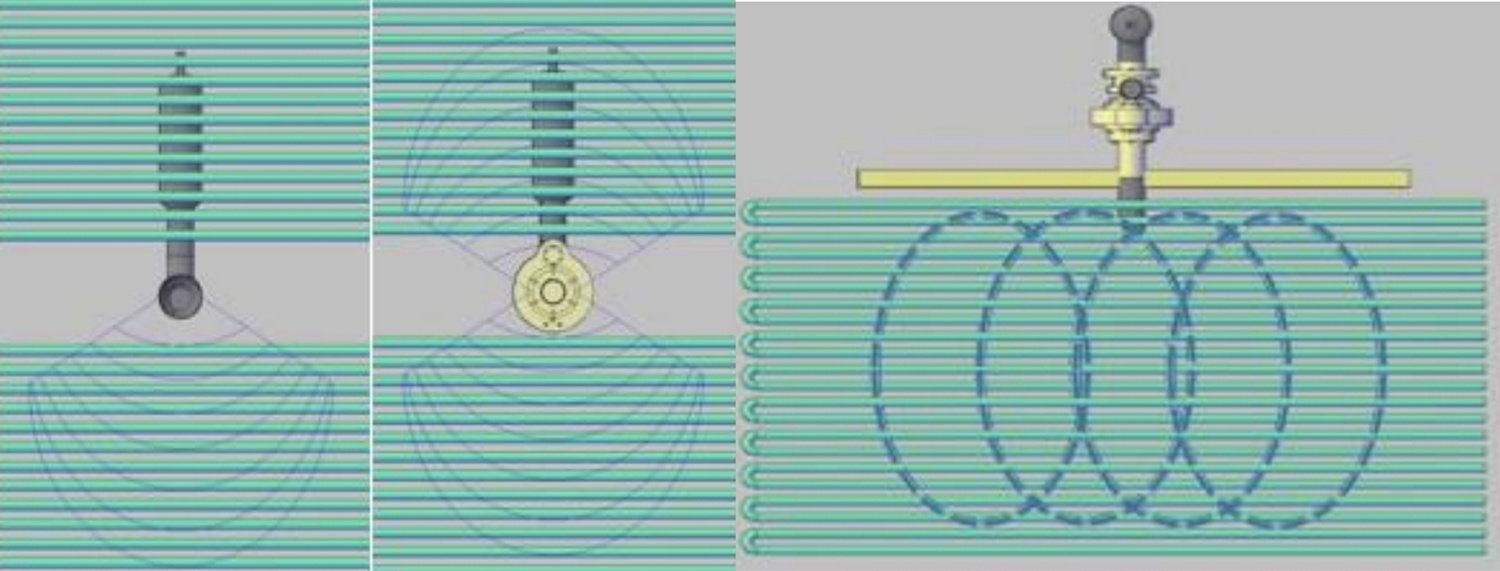

Rotary nozzle

The rotary gas nozzle is developed based on the original fixed gas nozzle, solving the limitations of fixed nozzle ash blowing.

The rotary nozzle can blow ash in all directions within a range of 0° to 360°, avoiding the shortcomings of having dead spots in ash blowing.

It can rotate continuously in both directions, stop at any angle, or step rotate according to set values;

Thorough ash blowing of the heating surface reduces the number of openings in the furnace body, significantly decreasing the number of pulse tanks, thereby reducing the boiler air leakage coefficient.

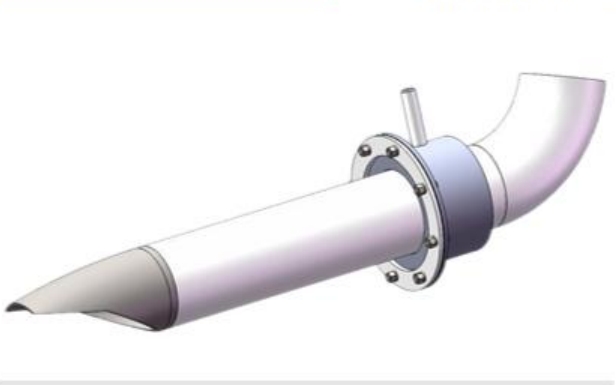

Spiral protective air nozzle

The pulse nozzle with spiral protective air is specially designed for boilers with ash accumulation and strong corrosion, aimed at solving issues of equipment corrosion and ash blockage.

The "pulse nozzle with spiral protective air" features a spiral guiding air inlet, installed close to the furnace wall. Compressed air from the spiral protective air device's inlet generates a spiral airflow curtain along the inner wall of the nozzle, creating a continuous wind curtain in the direction of the pulse nozzle, with spiral feeding that completely blocks the flue gas from entering the pulse nozzle.

→ Solves the corrosion phenomenon of the external pulse nozzle and elbow, extending the service life of the nozzle;

→ The convective cooling effect effectively avoids the occurrence of backfire;

→ During the system's operation, it does not affect the detonation gas flow direction on the heating surface, eliminating the need for timed switching on and off;

→ The system uses a high-pressure fan for independent air supply, accurately configuring the air volume without affecting the boiler operating parameters;

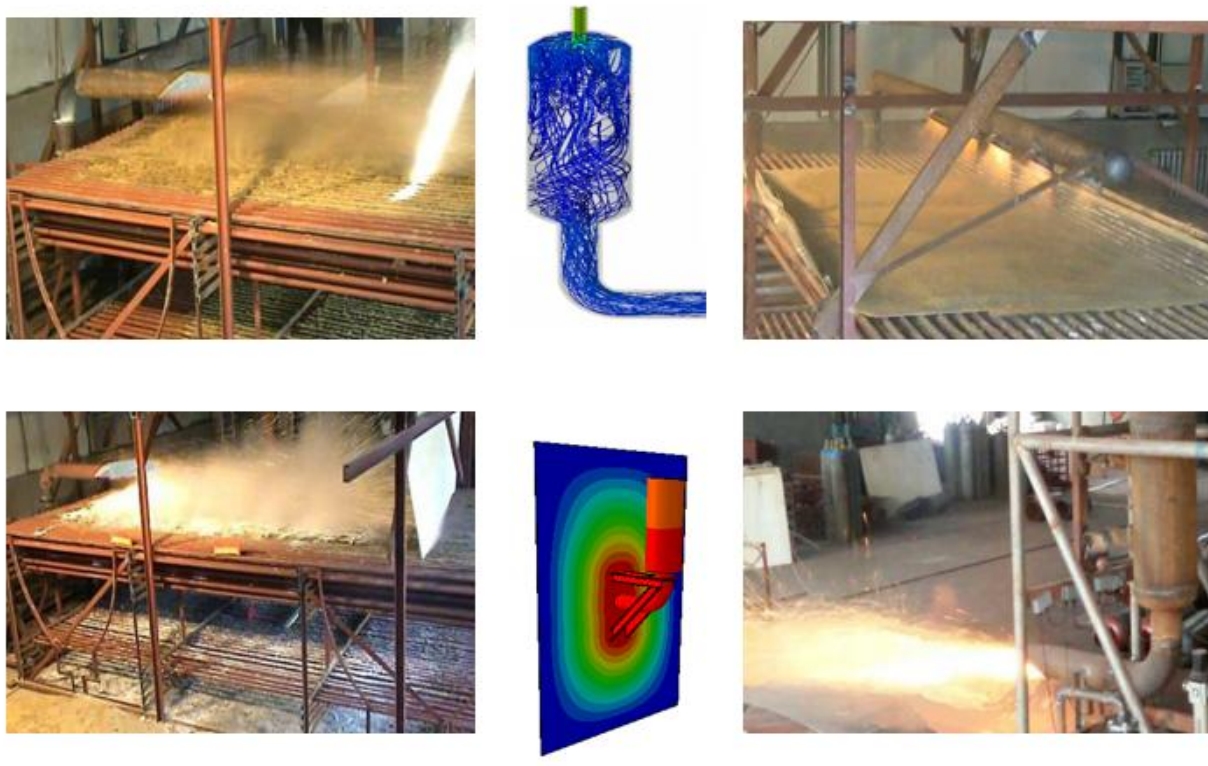

Experimental platform

It has a complete experimental simulation platform, continuously developing new series of products.

Installation example

Other Content

Project Inquiry

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.