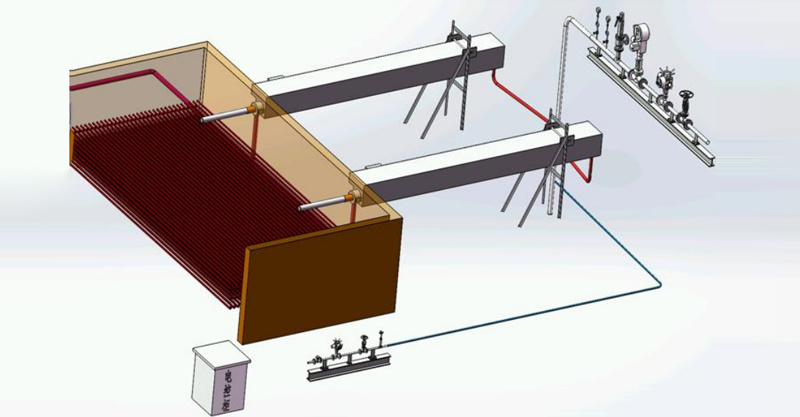

XD-2020ZC series steam soot blower

The steam blowing device uses high-temperature and high-pressure steam that is adjusted to flow through continuously changing rotating nozzles, which then ejects at high speed, generating a significant impact force to blow off the accumulated ash on the heated surface. The fly ash is carried away by the flue gas to achieve the purpose of removing the accumulated ash.

Key words:

Classification:

E-mail:

Product Description

01

Main body: furnace soot blower, long telescopic soot blower, fixed rotating soot blower, rake-type soot blower, etc.

02

Temperature and pressure reduction system: reduces superheated steam to the pressure and temperature used by the equipment.

03

Pipelines: including main steam pipeline, post-pressure reducing valve pipeline, condensate pipeline, back-blowing pipeline.

04

Condensate system: collects liquefied steam.

Furnace soot blowing

Applications

The furnace soot blower is used for cleaning the water-cooled wall surface of the boiler, suitable for cleaning furnace walls with heavy slag and flue gas temperatures up to 1800°C,

Structural principle

The general structure of the furnace soot blower is relatively small, the soot blowing pipe is a spiral pipe with two nozzles at the front end. First, through mechanical transmission, the front end of the spiral pipe is pushed into the furnace, and the valve opens to spray. The soot blowing pipe rotates while sweeping around or several rounds, forming a closed annular sweep on the water-cooled wall. After returning to the spray position, the valve closes, and the soot blowing pipe retracts to the standby position to protect the nozzle and threaded pipe from high-temperature erosion in the furnace.

Features

Equipped with 2 high-efficiency nozzles, thorough cleaning, stable operation.

Special valve design not only adjusts pressure but also uses a double-blade design to meet special working requirements.

Comprehensive cleaning of the water-cooled wall surface, leaving no dead corners.

Can achieve soot blowing angles of 180°, 240°, 300°, and other requirements.

Advantages

Compact structure, easy maintenance.

Interchangeable spare parts, low maintenance volume

Significant soot blowing effect, can improve thermal efficiency, stroke can be non-standard design.

| Main technical parameters | |

| Main soot blower stroke | 267mm (10.5") |

| Soot blower travel speed | 290mm/min |

| Soot blower rotation speed | 2.3r.p.m |

| Soot blowing pressure | ~1.5MPa |

| Soot blowing steam consumption and operation time | ~30kg/2.08min (sweeping 1 circle) |

| Nozzle diameter | 25.4mm (1") |

| Effective soot blowing radius | 1.5m~2m |

| Motor (used in China) | YSR-6324 B5 type 0.18kw 1440r.p.m |

| Power supply | 380V.3P.50Hz |

| Weight | ~110kg |

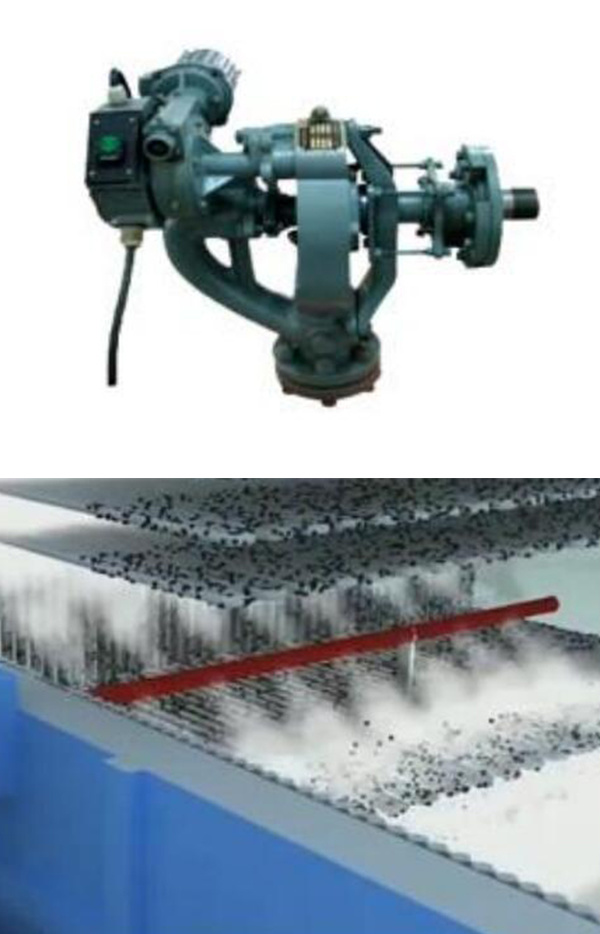

Long telescopic soot blowing

Applications

Mainly used for cleaning the heated surfaces of coal-fired boilers, biomass boilers, waste incinerators, etc., such as screen-type superheaters, convective superheaters, reheaters, economizers

and so on.

Structural principle

The long telescopic soot blower extends the soot blowing pipe into the furnace through rack mechanical transmission, while the soot blowing pipe rotates, and the Venturi nozzle arranged at the head of the soot blowing pipe performs a spiral extension movement, spraying the medium with appropriate momentum to clean the ash accumulation on the heated surface, improving the heat transfer efficiency of the boiler

Features

The gearbox and the walking box are not in the same housing, improving the reliability of the transmission device and ensuring that the gearbox lubricating oil does not leak. It has a wide application range and can be used under flue gas temperature conditions of about 600°C~1600°C.

The beam structure and moving parts are clear at a glance, and once a problem occurs, it is within reach. High-efficiency nozzles are used to ensure low gas consumption while meeting soot blowing requirements. The stroke T is generally less than 15m.

Advantages

Extremely convenient for maintenance, high interchangeability of parts.

Strong cleaning ability, extends boiler life, improves thermal efficiency,

Once an electrical fault occurs, there is a mechanical protection device.

| Main technical parameters | |

| Main soot blower stroke (T) | 2m-18m |

| Soot blower travel speed | 0.9-3.5mm/min |

| Soot blower rotation speed | 9-35r.p.m |

| Soot blowing pressure | ~1.5MPa |

| Soot blowing angle | 360° |

| Nozzle diameter | 12mm-32mm |

| Effective soot blowing radius | ~2m |

| Motor (used in China) | Y90S-4 B5 type 1440r.p.m |

| Power supply | 380V.3P.50Hz |

| Weight | (360-610)+T*135kg |

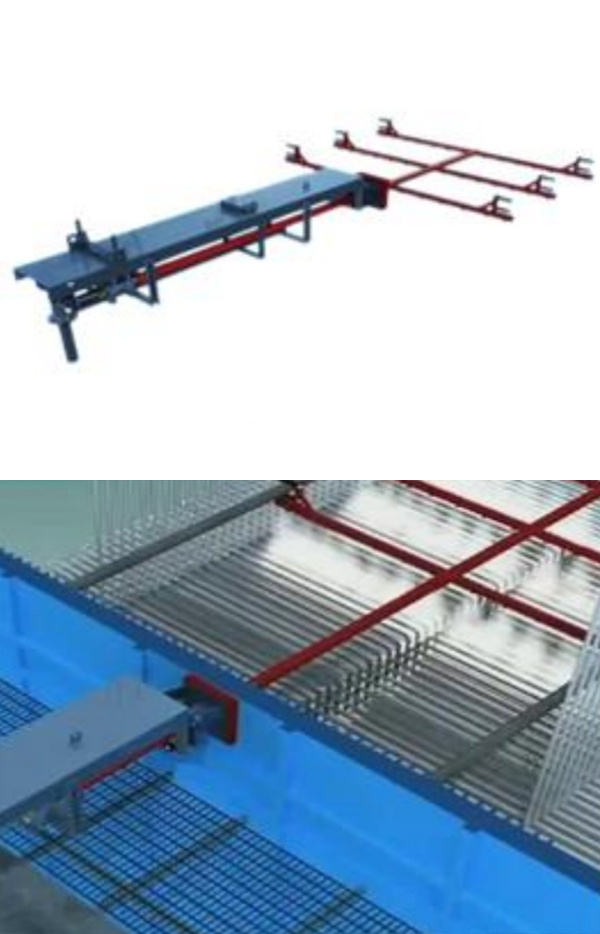

Rake-type soot blowing

Applications

Rake-type soot blowers are mainly used for cleaning the finned heated surfaces of economizers, the heated surfaces of air preheater tube bundles, and the ash accumulation on the surface of SCR denitration catalysts, with flue gas temperatures below 500°C.

Structural principle

The rake-type soot blower mainly consists of two major parts: the soot blower rake pipe inside the furnace and the soot blower pipe outside the furnace. When started, the rack and pinion mechanical drive pushes the soot blower pipe (outside) forward or backward without rotating. Several special branch pipes equipped with multiple nozzles are arranged on the central pipe, and the airflow ejected from the nozzles will clean the covered space without leaving dead corners, thus improving thermal efficiency.

Features

The multi-speed gearbox design can meet the cleaning requirements at different speeds.

Special design to cope with unique furnace structures to meet different internal support needs.

In the event of a malfunction of the limit switch, it can protect the mechanical transmission device.

The stroke T is generally less than 5M.

Advantages

Compact structure, reliable, and easy to maintain.

Professional design maximizes customer requirements.

The cleaning effect is significant and can effectively prevent the heating surface from clogging.

| Main technical parameters | |

| Main soot blower stroke (T) | <3.6m (single rake pipe) |

| Soot blower travel speed | 0.9m/min |

| Nozzle diameter | Adjustable as needed |

| Number of nozzles | Adjustable as needed |

| Soot blowing direction | Vertically downward |

| Soot blowing pressure | Adjustable as needed |

| Smoke temperature in the arranged area | 600℃ |

| Soot blowing medium | Steam or compressed air |

| Motor (used in China) | Y90L-4 B5 type 1440r.p.m |

| Power supply | (360-610)+T*135kg |

Fixed rotating soot blower

Applications

The fixed rotating soot blower is mainly used for cleaning the economizer and air preheater pipes on the boiler's rear flue, suitable for heat exchangers with flue gas temperatures below 600℃.

Structural principle

The soot blower pipe with multiple nozzles is left inside the furnace according to the arrangement of the pipes. When started, the reducer drives the soot blower pipe to rotate for one or several turns for comprehensive cleaning, with both inter-pipe cleaning and group pipe cleaning forms.

Features

Simple structure, no platform required, occupies little space, and has low cost

Few spare parts and simple maintenance.

Professionally designed according to customer needs, optimizing cleaning efficiency and improving thermal efficiency,

Suitable for cleaning with stroke T < 6m.

Advantages

Can meet cleaning at different angles from 30° to 360°.

Motor wiring is not affected, can work in both forward and reverse directions.

The product is reliable in use, with a low failure rate.

| Main technical parameters | |

| Soot blowing angle | 90°-335° |

| Soot blower rotation speed | 2.3r.p.m |

| Number of cleaning cycles each time | 1-2 (adjustable) |

| Soot blowing radius (m) | 1-1.5 |

| Soot blowing pressure | 0.9-1.1 (adjustable) |

| Soot blowing consumption | 30-100Kg/min |

| Soot blowing medium | Steam or compressed air |

| Motor (used in China) | YSR-6324 B5 type 1440r.p.m |

| Power supply | 380V.3P.50Hz |

| Weight | ~75kg |

Comparative analysis of gas soot blowers, steam soot blowers, acoustic soot blowers, and air energy soot blowers

| Gas soot blower | Steam soot blower | Acoustic soot blower | Air energy soot blower | |

Medium and parameters |

|

| Compressed air P>0.4MPa—0.6MPa | Compressed air P>0.6MPa—0.8MPa | |

Scope of application and usage method | Scope of application and usage method: convection tubes | loose ash. Each soot blower runs for about 5-10 minutes, and the boiler continues to operate without stopping. | 使用范围和运行方式:对流受热面、 | 使用范围和运行方式:对流受热面、 | |

Advantages | 吹灰效果干净、彻底,吹灰频 | The blow-off effect is obvious, for materials with weak adhesion or loose | Low investment cost, small footprint, using air | Using compressed air as the blow-off medium, various | |

Disadvantages | Requires professional design manufacturers for targeted | High investment, blow-off directly acts on the pipe wall, easy | Needs to run continuously, blow-off effect is not obvious, low efficiency. | High energy consumption, rotating parts are prone to damage, blow-off | |

Cost | 100% | 150%——250% | 90%——120% | 100%——150% | |

Operation and maintenance costs | 100% | 1500%——2500% | 500%——700% | 500%——700% | |

Installation examples

Other Content

Project Inquiry

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.